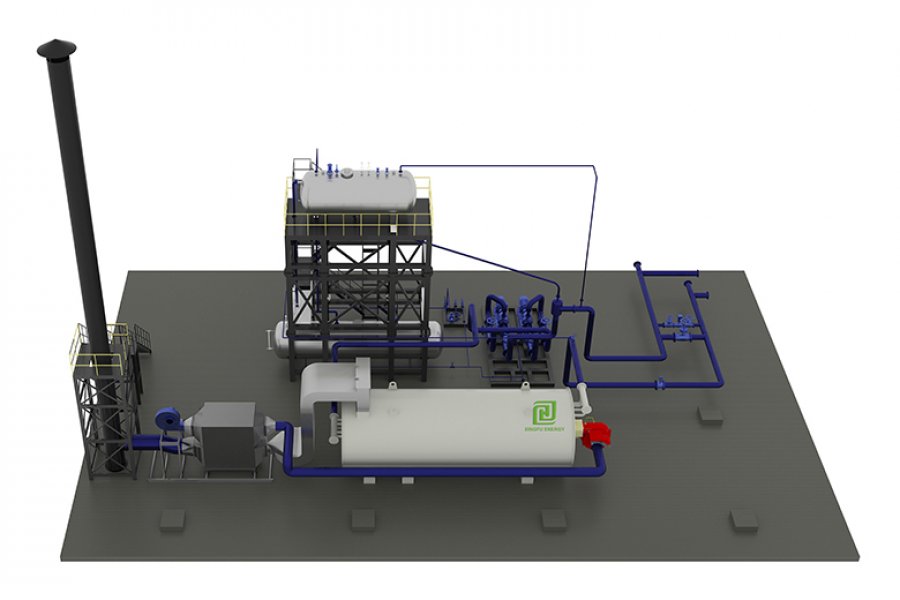

Main Technology Application

1. It adopts a wet-back internal combustion two-pass structure, and the top of the boiler is equipped with a top coil, which effectively prevents the flame from directly radiating to the rear wall. At the same time, under the premise of a compact structure, it increases the radiation heating area and improves the thermal efficiency of the boiler.

2. The use of micro-positive pressure operation effectively improves the combustion intensity of the furnace, makes the volume of the boiler with the same capacity smaller, eliminates the air leakage of the boiler furnace and flue, and improves the thermal efficiency of the boiler.

3. Adopt advanced EDA technology to calculate the size of the furnace body and the flow rate of flue gas in detail, and make full use of flame and flue gas heat exchange to ensure reliable operation and sufficient cooling of the boiler, and improve the thermal efficiency of the boiler.

4. The high-efficiency condensation technology is adopted to effectively reduce the exhaust gas temperature and improve the thermal efficiency of the boiler.

5. Reasonable structural design and excellent refractory and heat preservation materials are adopted to greatly reduce the external temperature of the furnace body, making the external temperature lower than 50 degrees (higher than the national standard), reducing heat loss and improving the thermal efficiency of the boiler.

6. It adopts a new design to reduce the emission of harmful substances during fuel combustion and meet the national environmental protection standards, especially to reduce the emission of nitrogen oxides and meet the national low nitrogen emission standards.

7. Imported burners of many well-known international brands are used to adapt to various application scenarios, ensuring quality and safety.

8. Adopt PLC and other automation controllers of international brands such as Siemens as the control core, and also use peripheral components of international brands to realize a high-quality fully automatic control system, which can collect various import and export temperatures, pressures, etc. in real time. The parameters are displayed centrally in the control cabinet in real time. Through the closed-loop control system such as PID, the boiler is guaranteed to work stably under various parameters set by the user. At the same time, the working range of the data is monitored, and various abnormalities are reminded or alarmed, which is convenient for users. use and maintenance. The control module also has powerful expansion capabilities, and can conveniently realize various in-depth applications such as group control and remote control according to customer needs.